- Structural Support and Lightweight

- Sealing and Protective Performance

- Weather Resistance and Anti-Aging

- Safety and Fire Protection

- Flexible Design and Economy

- Aesthetic Design is more Fashionable

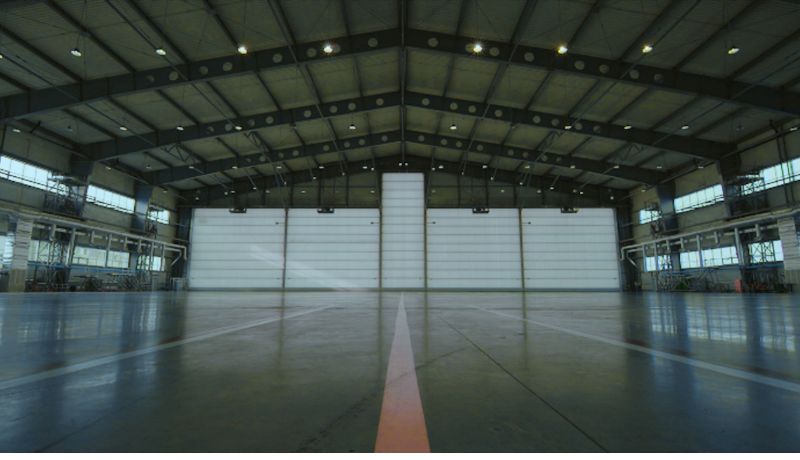

Fabric PVC combines strength, sealing and weather resistance, making it an ideal material for hangar doors, especially for large aviation facilities that require frequent opening, high protection requirements and lightweight.

1、Structural Support and Lightweight

Two layers of polyvinyl fluoride are used as the base material, and the surface is coated with a PVC layer to form a composite material. It not only maintains a rigid structure, but also has a light weight, which is suitable for the opening and closing needs of large hangar doors and reduces the burden of mechanical drive. In daily large-scale building doors, the combination of structural support and lightweight can effectively reduce the energy consumption and building material consumption of frequent opening and closing of doors.

2、Sealing and Protection Performance

PVC coating can form a dense waterproof layer, effectively blocking rain, dust and corrosive substances from entering the hangar. Hangars or similar large equipment storage areas usually protect precision equipment and have high requirements for constant temperature, humidity and air purity. The relatively closed environment formed by PVC coating can protect aircraft and equipment. At the same time, its elastic properties can also provide a good sealing effect when the door is closed, further enhancing the effect of reducing air leakage.

3、Weather Resistance and Anti-Aging

PVC material has excellent UV resistance and temperature resistance. It can maintain the relative stability of the indoor environment in extreme environments of -40℃ to 50℃. It is not easy to crack or fade in long-term outdoor use, which can ensure the daily use of the hangar door and the aesthetic pursuit of the hangar door, extending the service life of the hangar door.

4、Safety and Fire Prevention

The PVC materials used in some hangar doors will be added with flame retardants to meet fire prevention standards. The flame retardant can achieve self-extinguishing in 3 seconds, delaying the spread of fire in accidental fires and ensuring the safety of personnel and equipment. It can achieve peace of mind in one step and everywhere, allowing large and expensive equipment and facilities to be stored with peace of mind.

5、Flexible Design and Economical

Fabric PVC can be customized into different sizes and shapes according to the size of the door opening, adapting to hangars with special structures or other scenarios. Compared with metal or other composite materials, it is cheaper and easier to maintain and replace. It has better economic benefits.

6、Aesthetic Design is more Fashionable

PVC materials can achieve rich color options through surface coating technology, such as matte black, metallic gray, silver white, etc., which can echo the modern architectural style of airport terminals, industrial plants, etc., and realize the aesthetic unity of Fabric PVC, Fabric Hangar Doors and surrounding landscapes.

Fabric PVC achieves a balance between functionality and economy in hangar doors, and is particularly suitable for situations that require lightness, durability and fast operation.